Business Evolution in the Age of Modern Technologies: A Deep Dive into Electronics, 3D Printing, and Mobile Crushing Screening Plants

In today’s rapidly transforming industrial landscape, the integration of advanced technological solutions is not just a competitive advantage but a necessity for sustained growth and success. Businesses leveraging innovations in electronics, 3D printing, and specialized equipment such as the mobile crushing screening plant are positioning themselves at the forefront of their industries. This comprehensive article explores these themes in detail, offering insights into how they are revolutionizing business operations, enhancing productivity, and opening new avenues for growth.

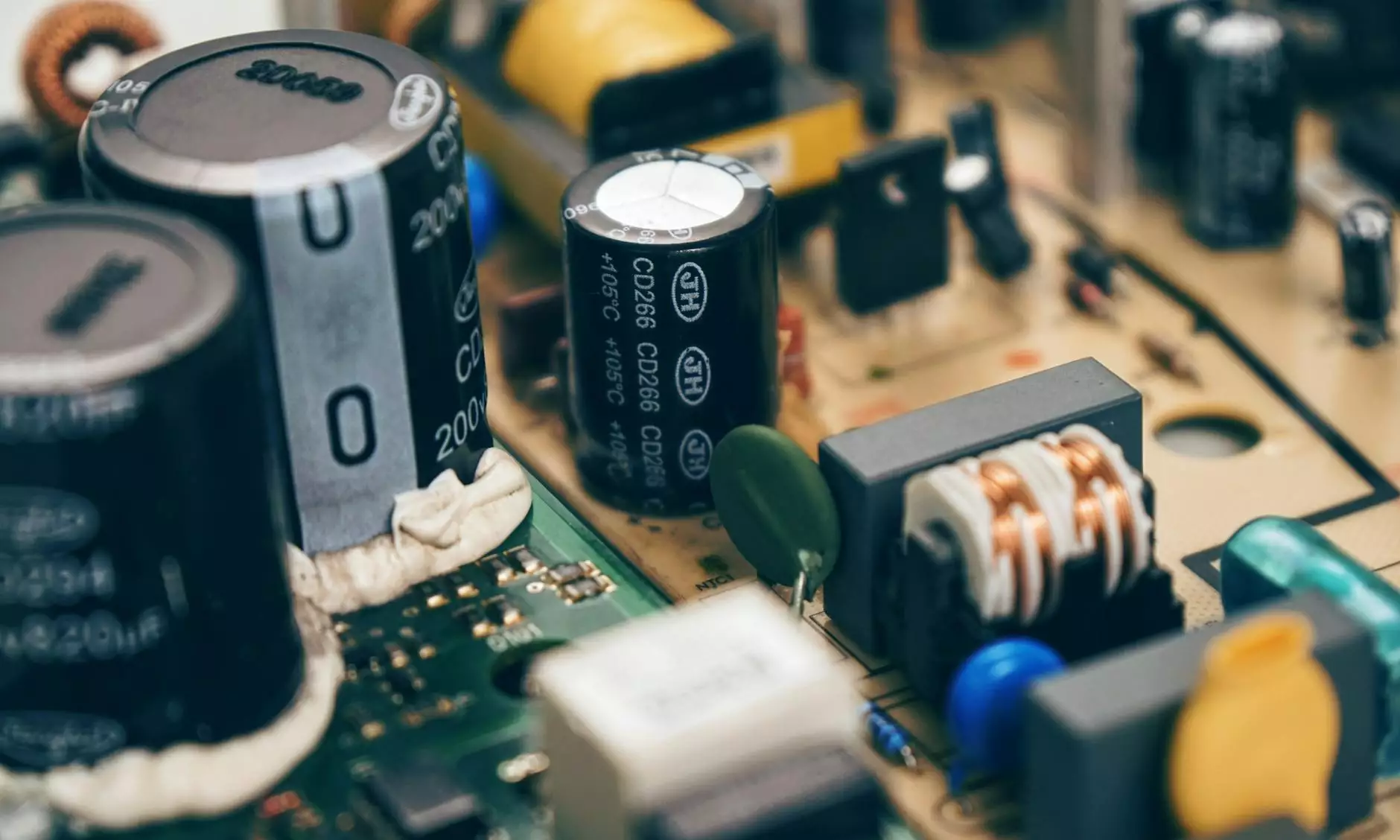

Understanding the Foundation: The Role of Electronics in Modern Business

Electronics form the backbone of almost every industry today. From automation systems to communication networks, electronic components underpin the operational efficiency of businesses. High-quality electronics enable seamless data processing, reliable communication, and precise control of manufacturing processes.

The Impact of Electronic Innovations on Business Operations

- Automation and Robotics: Modern electronics have enabled the deployment of sophisticated automation systems that reduce manual labor, increase precision, and enhance safety.

- IoT (Internet of Things): Connecting devices through the internet facilitates real-time data collection and analysis, leading to smarter decision-making processes.

- Enhanced Communication: Advanced electronic communication tools ensure faster, more secure collaboration across geographic boundaries.

The Future of Electronics in Business

As electronic components continue to evolve with faster processing speeds, lower energy consumption, and increased miniaturization, future business models will likely integrate AI-powered electronic systems, augmented reality interfaces, and interconnected IoT devices to optimize operations even further.

Revolutionizing Manufacturing with 3D Printing Technology

The emergence of 3D printing has revolutionized manufacturing, prototyping, and product development across industries. Its ability to produce complex geometries with high precision, reduce waste, and accelerate production cycles makes it an indispensable tool for modern businesses.

Advantages of 3D Printing in Business Environments

- Rapid Prototyping: Designs can be turned into tangible prototypes within hours, allowing for swift testing and iteration.

- Customization: On-demand, tailored products can be produced efficiently without the need for costly molds or tooling.

- Cost-Effective Production: Reduces material waste and lowers manufacturing costs, especially for small batch or custom components.

- Supply Chain Optimization: Localized 3D printing can minimize reliance on distant suppliers, reducing lead times and inventory costs.

The Future Outlook for 3D Printing in Business Strategy

Looking ahead, advancements in material science, multi-material printing, and integration with digital supply chains will enable businesses to create even more intricate and functional products. Industries like aerospace, healthcare, automotive, and electronics are already harnessing these innovations for competitive advantage.

Introducing Mobile Crushing Screening Plants: Essential Equipment for Modern Construction and Mining Businesses

The mobile crushing screening plant is a pivotal piece of equipment in the construction, mining, and recycling industries. Its mobility, efficiency, and adaptability make it ideal for large-scale projects requiring versatile material processing.

Advantages of Using Mobile Crushing Screening Plants

- Flexibility and Mobility: Easily relocate the plant across different sites, reducing transportation costs and time delays.

- Efficiency in Material Processing: Capable of crushing and screening raw materials such as stones, ores, and construction debris into desired sizes, facilitating reuse or further processing.

- Cost Savings: Eliminates the need for multiple stationary equipment setups, minimizing infrastructure investments in fixed locations.

- Environmental Benefits: Supports eco-friendly practices by recycling waste materials, reducing environmental impact, and minimizing landfill use.

The Technical Advantages of Modern Mobile Crushing Screening Plants

High-capacity engines, advanced control systems, and durable wear parts ensure these plants operate with minimal downtime, high throughput, and superior quality of processed material. Their modular design allows easy customization based on project needs, from small-scale applications to large infrastructure projects.

Integration of Technologies for Industry 4.0 in Business

The concepts of Industries 4.0 synthesize electronics, 3D printing, and mobile crushing screening technology into a connected digital ecosystem. This integration fosters smarter operations, predictive maintenance, real-time analytics, and enhanced supply chain management.

Real-World Applications and Success Stories

- Smart Manufacturing: Incorporation of IoT-enabled machinery for predictive diagnostics, reducing unplanned downtime.

- Customized Production: 3D printing allows rapid adaptation to market demands, enabling businesses to quickly introduce new products.

- Efficient Resource Utilization: Mobile crushing plants supported by data analytics optimize material handling and processing.

Choosing the Right Technology Partner: Why Polygonmach Leads the Industry

To succeed in these technological domains, selecting a reputable, innovative partner is crucial. Polygonmach stands out as a leader in providing high-quality, reliable solutions for electronics, 3D printing, and mobile crushing screening plants. Their commitment to research, development, and customer satisfaction makes them the ideal choice for businesses aiming to leverage these advanced technologies.

What Makes Polygonmach the Preferred Partner?

- Comprehensive Product Range: From advanced electronic components to innovative 3D printers and mobile crushing units.

- Custom Solutions: Tailored services to meet specific operational needs and industry standards.

- Global Presence: Extensive after-sales service and support network worldwide.

- Innovative Research & Development: Continuous improvement and cutting-edge technological integration.

Final Thoughts: Embracing the Future of Business Technology

In conclusion, the synergy between electronics, 3D printing, and mobile crushing screening plants is transforming industries across the globe. These technologies not only enhance operational efficiency and reduce costs but also open new pathways for innovation and competitive differentiation.

Businesses that proactively adopt these cutting-edge solutions position themselves better for future challenges, market fluctuations, and emerging opportunities. Collaboration with industry leaders like Polygonmach ensures that companies receive the most advanced, reliable, and customized technological tools to propel their growth.

Embark on Your Digital Transformation Today

It is essential for forward-thinking enterprises to embrace technological advancements to stay ahead. Whether it's integrating electronics for automation, utilizing 3D printing for rapid product development, or deploying mobile crushing screening plants in construction projects, these investments will yield significant long-term benefits.

Partner with trusted providers, stay updated on industry trends, and continuously innovate to lead your industry into the future with confidence.