Unlocking the Potential of FDM (Fused Deposition Modeling) in Art Supplies, Product Design, and 3D Printing

The realm of 3D printing has revolutionized numerous industries, from art and design to manufacturing and engineering. Among the various 3D printing technologies, FDM (Fused Deposition Modeling) stands out as one of the most accessible, versatile, and cost-effective methods. Its adaptability makes it an invaluable tool within the creative and industrial sectors, including art supplies, product design, and innovative manufacturing processes at arti90.com.

What is FDM? An In-Depth Exploration

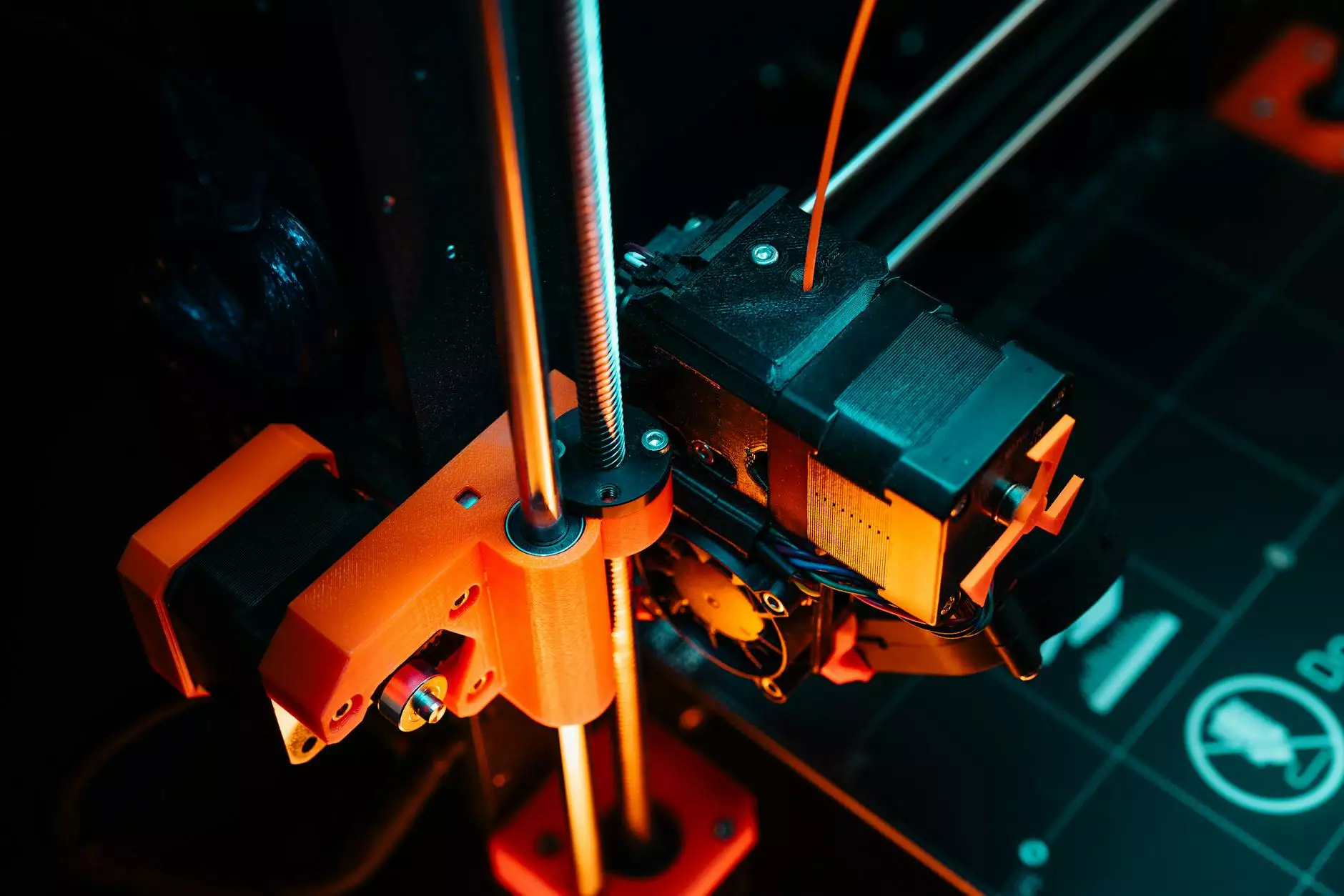

FDM, or Fused Deposition Modeling, is a layer-by-layer additive manufacturing process that extrudes thermoplastic filaments to build complex three-dimensional objects. Originally developed in the late 1980s, FDM has become one of the most popular techniques due to its simplicity, affordability, and continuous technological advancements.

Unlike subtractive manufacturing processes that cut away material to create a shape, FDM adds material precisely where needed, allowing for rapid prototyping, custom art pieces, and functional product components. This method employs a heated nozzle to melt thermoplastic filaments such as ABS, PLA, PETG, and other specialty materials, depositing them with high precision onto a build platform.

Advantages of FDM in Creative and Industrial Applications

- Cost-Effective Production: FDM machines and materials are relatively affordable, making 3D printing accessible to artists, designers, and small businesses.

- Material Versatility: A wide variety of filament options enables the creation of durable, flexible, and aesthetically appealing objects.

- Design Flexibility: Rapid iteration and customization are possible, reducing development time and allowing for innovative art and prototypes.

- Ease of Use: Modern FDM printers feature user-friendly interfaces and automated calibration, making the technology approachable for beginners and experts alike.

- Scalability: From small-scale artistic pieces to larger industrial prototypes, FDM can handle projects of diverse sizes and complexities.

The Role of FDM in the Art Supplies Industry

The application of FDM technology in art supplies is transforming traditional practices by offering artists new tools for creativity. Through detailed modeling, customized tools, and innovative materials, artists can push the boundaries of their crafts.

Creating Custom Art Tools and Accessories

Artists can design and produce bespoke tools tailored to their specific needs, such as uniquely shaped brushes, palette knives, or sculpture supports. The ability to rapidly prototype and iterate enables real-time adjustments, enhancing artistic workflows. For example, complex brush handles or intricate sculpting molds can be produced with FDM, improving ergonomic comfort and artistic precision.

Designing Unique Art Pieces and Installations

FDM allows artists to craft large-scale sculptures, installation pieces, and intricate decorative elements with high detail and customization. Moreover, using specialty filaments like metallic or transparent materials, artists can create visually stunning works that would be impossible or costly with traditional methods.

Integration with Mixed Media Art

By combining FDM-printed components with other mediums such as resin, glass, or traditional sculpture, artists can develop hybrid artworks that are both innovative and captivating. The flexibility of FDM enables seamless integration into complex art projects and exhibits.

Transforming Product Design with FDM

The manufacturing landscape benefits immensely from FDM by enabling rapid prototyping, functional testing, and even small-batch production. For product designers, this means faster time-to-market and greater creative freedom.

Rapid Prototyping and Testing

Designers can develop functional prototypes that accurately mimic final products, allowing for testing, validation, and iterative improvements before committing to mass production. FDM expedites the development cycle, reduces costs, and enhances innovation capabilities.

Customization and Personalization

Consumers increasingly expect personalized products. FDM technology permits the creation of customized items such as ergonomic tools, personalized gadgets, and tailored consumer goods. This customization fosters brand loyalty and meets individual user needs efficiently.

Functional and End-Use Components

Advances in material science—such as high-strength thermoplastics and composites—have expanded the application scope of FDM beyond prototypes. Manufacturing end-use parts with complex geometries, internal channels, and lightweight designs is now feasible, making FDM an attractive option for small batch manufacturing and bespoke components.

Innovative 3D Printing with FDM at Arti90.com

At arti90.com, we emphasize leveraging FDM technology to bridge creativity and industrial advancement. Our extensive selection of high-quality filament materials, including eco-friendly options, ensures that artisans and manufacturers can achieve their unique project goals.

State-of-the-Art Equipment and Materials

We supply cutting-edge FDM printers capable of delivering precision, reliability, and speed. Coupled with our curated range of filaments—such as PLA, ABS, PETG, Nylon, TPU, and specialty composites—our clients unlock diverse possibilities from artistic models to industrial parts.

Expert Support and Custom Solutions

Our team of experts offers guidance on designing for FDM, selecting suitable materials, and optimizing print settings. Whether you're an artist seeking to produce complex sculptures or a product developer prototyping new gadgets, our tailored solutions enable seamless integration of 3D printing into your workflow.

The Future of FDM and Its Impact

The continuous evolution of FDM technology involves developments such as multi-material printing, higher resolution, faster print speeds, and more sustainable materials. These advances promise to further revolutionize art creation, product development, and manufacturing in several ways:

- Enhanced Material Science: Introduction of bio-based, recycled, and composite filaments to promote sustainability.

- Multi-Material and Multi-Color Printing: Enabled by advanced nozzles and extruders, allowing for complex, colorful designs.

- Higher Resolution and Accuracy: Improving surface finish and fine detail reproduction essential for art and intricate prototypes.

- Automation and Smart Integration: IoT-enabled printers providing real-time monitoring, adjustment, and remote operation.

Embracing FDM for Creativity and Industry Innovation

As the FDM technology continues to mature, its role in expanding human creativity and industrial production becomes ever more prominent. By choosing arti90.com as your partner, you gain access to the latest innovations, top-tier materials, and professional support to leverage FDM’s full potential.

Why Choose arti90.com for Your FDM Needs?

- Comprehensive Product Range: From printers to high-quality filaments and accessories.

- Expert Technical Support: Ensuring optimal results regardless of project complexity.

- Custom Solutions: Tailored equipment and material recommendations for special applications.

- Educational Resources: Workshops, tutorials, and design tips to maximize the impact of your FDM projects.

Conclusion: Empower Your Creativity and Manufacturing with FDM

The strategic integration of FDM (Fused Deposition Modeling) into your artistic or industrial process opens a world of possibilities. With its unmatched flexibility, cost-effectiveness, and continual technological advancements, FDM is poised to dominate the future of art supplies, product design, and 3D printing.

Partner with arti90.com today to unlock the full potential of FDM technology, access premium materials, and receive expert guidance tailored to your specific needs. Embrace the future of creative and industrial manufacturing—where imagination meets innovation through the power of FDM.